27 Jun Tech Tip Tuesday: How to choose the right hydraulic pump to keep your equipment moving

Note that this information applies only to Power-Packer products manufactured in North America.

Whether you need a basic hydraulic hand pump or are looking for a more advanced pump that activates at the touch of a button, Power-Packer has a variety of hydraulic pumps that will easily integrate into your application.

A basic hand pump comes with a selector valve, reservoir sized for cab-tilt applications, vented fill plug and a relief valve for safe operation. These pumps are highly effective solutions for cab-tilt power units. For applications where time is essential, we offer air and electric upgrades. The air and electric cab pump product lines will provide all the advantages of our hand pumps, with the addition of automation and increased speed.

|

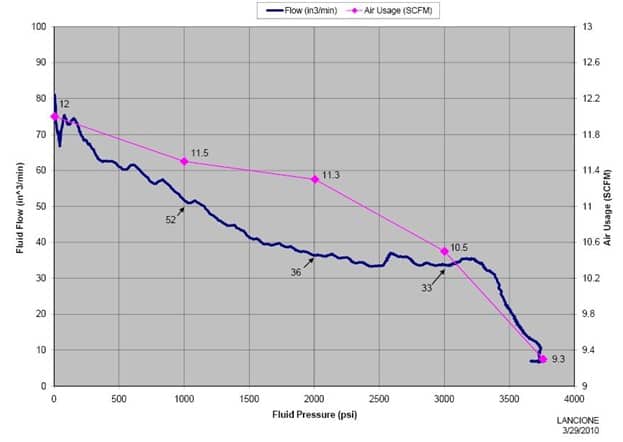

Air power units Power-Packer’s air power units require an external air supply to operate. The operating pressure should be at a minimum of 60 psi and a maximum of 120 psi. We recommend a supply line with a 3/8-inch inside diameter and a minimum flow rate of 8 standard cubic feet per minute. A standard Schrader valve connection is available to connect shop air for maintenance or assembly. A ¼-18 NPTF is available for the main supply line. A shuttle valve separates the two connections so you can use the Schrader valve without needing to disconnect the main supply line. The packaging space for these units increases in relationship to the hand pumps. The air motors will add approximately 7.4 inches of required space. See Figure 1 for the performance curve. |

Electric power units

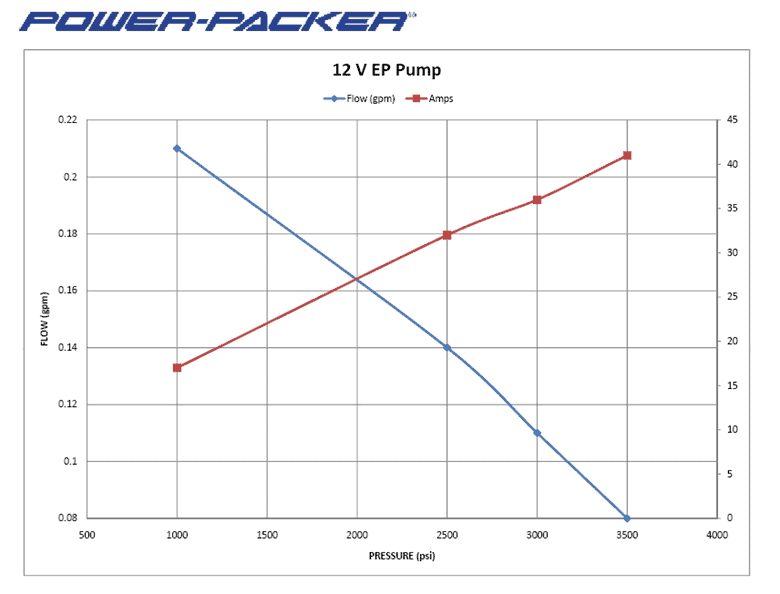

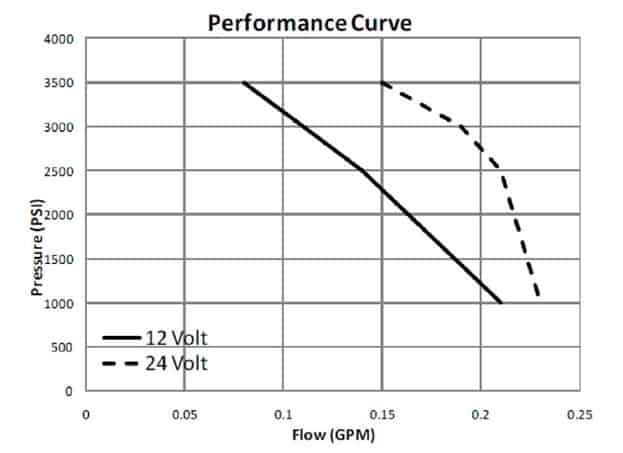

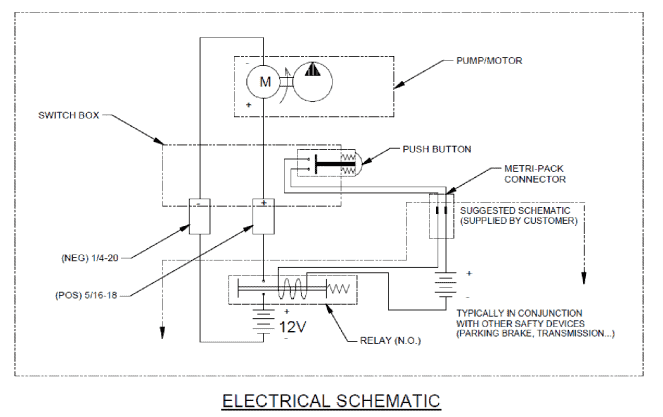

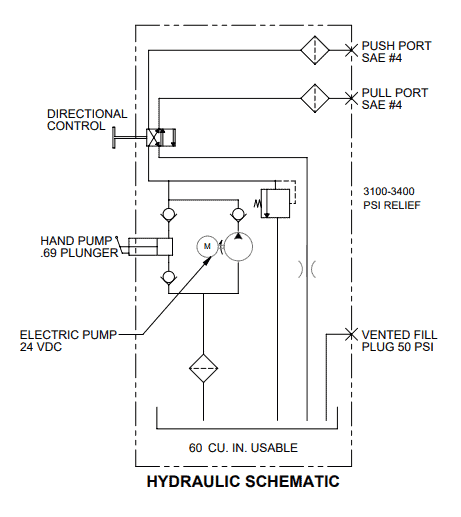

Electric power units are available in 12- and 24-volt options. Review the flow and amp draw in Figures 2 and 3 below. The electrical schematic is outlined in Figure 4, and a sample hydraulic schematic is shown in Figure 5. We offer a model-specific starter interlock as an additional safety option. The motor will add approximately 5.4 inches of additional necessary space.

Figure 2: Flow vs. Amp Draw

Figure 3: Electric Pump Performance Curve

Figure 4: Electrical Schematic – Electric Pumps

Figure 5: Hydraulic Schematic – Electric Pumps

Questions about Power-Packer hydraulic pumps? Contact our Customer Service team at info@powerpackerus.com for more information.