12 Dec Tech Tip Tuesday: How to integrate stabilization system into your equipment

Power-Packer’s self-contained stabilization systems have two main components: stabilization legs and control boxes. This complete system means you may operate the legs separately from your equipment’s other hydraulic systems. While an isolated system approach has advantages, there are some situations where integrating a stabilization system into your equipment’s current hydraulics may make more sense. Integrating Power-Packer’s hydraulic stabilization legs is simple, but there are a few factors to consider:

Flow rate

Power-Packer’s stabilization legs all come with load-holding valves, either counterbalance or pilot-operated check valves, built into the end of the cylinder. Each of these valves has a specific maximum flow rate (See table below). When connecting your power unit to the stabilization or jack legs, be sure flow rates do not exceed the settings on the load-holding valves.

Flow rate

| Bore size (inches) | Valve type | Maximum flow rate (GPM) |

| 3 | Pilot-operated check | 5 |

| 3.5 or 4 | Pilot-operated check | 5 |

| 3.5 or 4 | Counterbalance | 3 |

| 5 or 6 | Pilot-operated check | 5 |

| 5 or 6 | Counterbalance | 15 |

Operating valves

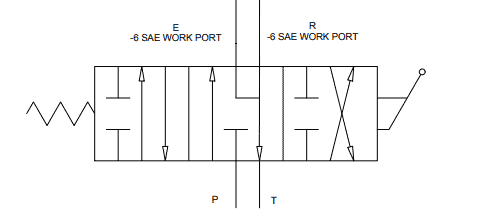

Power-Packer’s hydraulic jack legs must be operated with a motor spool (open center) valve. These valves are typical for cylinders that have integral load-holding check or counterbalance valves. If a counterbalance valve reaches its cracking pressure, the oil needs to flow back to the tank or low-pressure lines. The figure below shows our standard valve block with work ports, which allow oil to flow back to the tank in the center position.

Standard valve block with work ports

Operating pressure

Our stabilization legs are set to operate at 2,500 psi nominal. We do allow the operating pressure to increase up to 3,000 psi, with the load-holding valves set to relieve the pressure at 3,500 psi. The load capacity of our legs is defined at 2,500 psi pressure, which should be considered when designing your system.

Connections and hoses

The work ports on our stabilization legs are female #6 SAE ports (9/16 to 18 inches). Some legs will come with fittings on the manifold block. These fittings will have a male 37-degree JIC connection for the hoses (straight, 45- or 90-degree elbow). You may also use male #6 to male ORSF fitting adaptors for O-ring face seal connections.

If you have questions about Power-Packer’s self-contained stabilization systems and the advantages of integrating them with your vehicle or equipment’s hydraulics, please contact our Customer Service team at info@powerpackerus.com.