24 Jul Tech Tip Tuesday: How Power-Packer’s stabilization leg design helps prevent hydraulic system contamination

In the aggregate and construction industries, where stabilization legs are consistently used in mobile applications, it can be challenging to prevent contaminants from entering the hydraulic system.

Whether it’s a crushing plant, conveyor, or screen plant, these applications introduce a risk of damage to exposed portions of a stabilization leg. Rocks may drop or shake loose, scratching or denting the extended leg. The dusty, dirty environment will also cause contamination to build up on the rod or seal area.

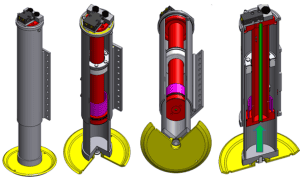

The tube-in-tube design of Power-Packer’s stabilization legs isolates the rod and seals from external damage, ensuring an extended life in rough and harsh environments. With our design, the seals don’t connect with any exposed part of the stabilization leg. This prevents environmental scratches or dents from damaging the rod and seal surfaces (See Figure 1). It also blocks any contamination from building up around the rod and seal area, which can damage the cylinder’s sealing capability.

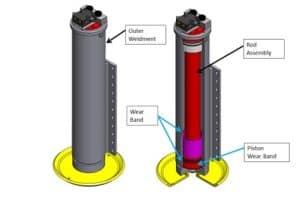

As the leg extends or retracts, the wear bands in the outer well tube are the only soft parts that are exposed to external contaminants (See Figure 2). These bands keep the cylinder barrel in line during operation. In addition, the wear bands will remove built up dirt from the exposed portion of the leg as it retracts, further protecting the hydraulic seals. For an extra layer of protection and to increase the service life, the space between the two wear bands is also greased.

Questions about Power-Packer stabilization legs? Contact our Customer Service team at info@powerpackerus.com for more information.

Note that this information applies only to Power-Packer products manufactured in North America.