30 Oct The Fall and Rise of Cabover Engine Trucks

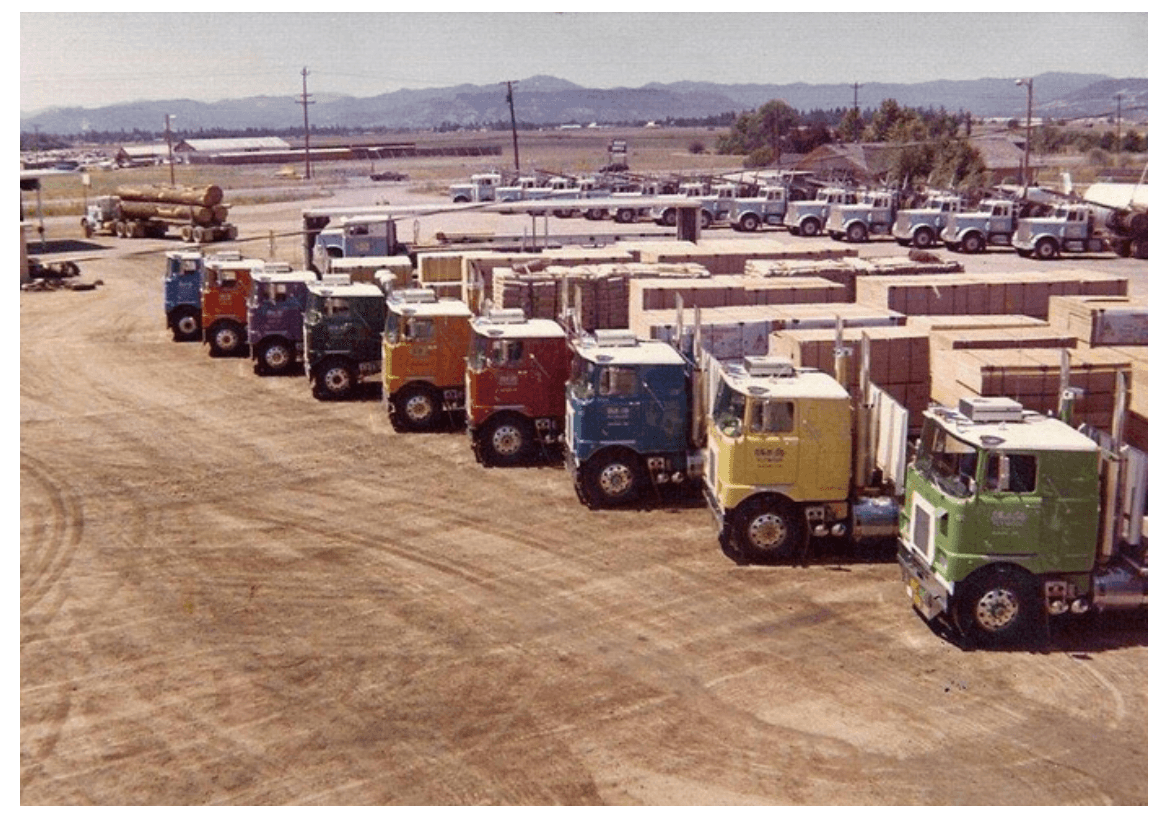

Cabover engine (COE) trucks were once a common sight on America’s roads. In these big rigs, the passenger cabin literally sat on top of the engine compartment. While dominant in the U.S. into the 1970s, semi-truck length laws and safety issues led to the development of cabs with long hoods, slowing production of COEs almost to a halt. Today, COEs remain standard in Europe and Asia, but conventional cabs own the Class 8 heavy-duty truck market in the States.

Despite the use of long hood designs for Class 8 trucks, the COE has retained popularity in the U.S. for a large roster of medium-duty vocational applications, such as fire and rescue, urban delivery, lawn maintenance, waste vehicles and other markets that demand exceptional maneuverability and visibility. In these applications, the cabover’s flat nose and wide windshield make it easier, and often safer, for drivers to navigate tight city streets and highly populated areas. The shortened wheelbase allows for an extremely tight turning radius, making COEs ideal for backing into driveways and winding through city traffic.

Cab Tilt Systems Allow Easy Maintenance and Repair

With their engines fully covered by the cab, COE trucks require robust and reliable built-in cab tilt systems. This integral component tilts the entire cab forward, allowing fast and easy access to the engine for maintenance and repair.

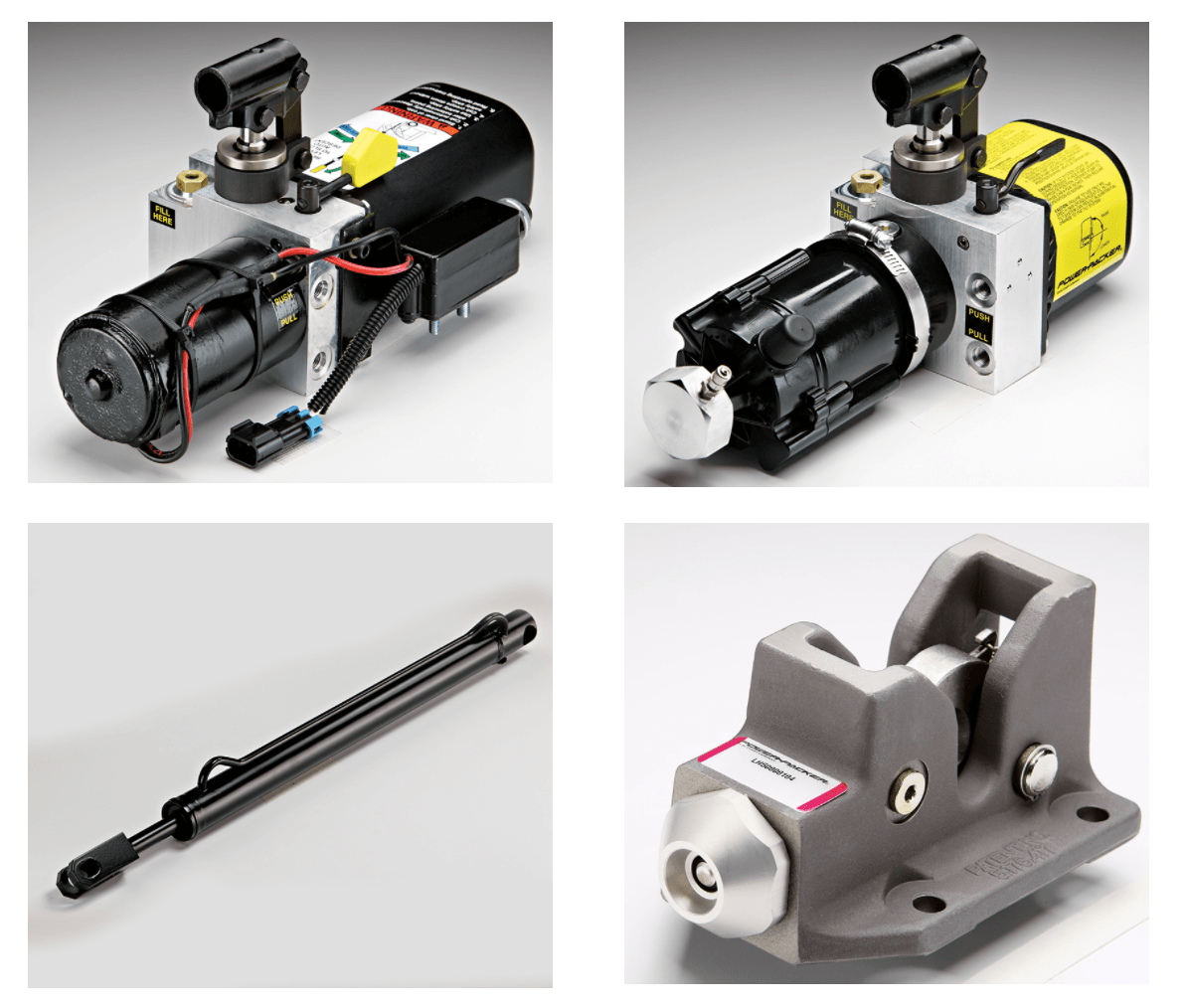

Power-Packer is a leader in hydraulic cab tilt systems and a trusted supplier to COE OEMs worldwide. Our complete range of pumps, cylinders and latches make it possible for us to design a cab tilting system that is perfectly matched to an application. Combining our hydraulic cylinders with any of our hydraulic pumps – whether electric, air or manually powered – we can offer a better fitting system, which results in a better performing system and a safer, more efficient and productive work environment.

The above Power-Packer components combine to create a reliable and efficient cab tilt system. (top) hydraulic pump options (bottom) hydraulic cylinder and latch

Benefits of a Power-Packer Cab Tilt System

Power-Packer hydraulic pumps, cylinders and latches combine to create some of the most powerful and durable hydraulic motion control systems available anywhere. Our engineers understand the harsh environments and rigorous demands of on- and off-road equipment, military operations, and fire and rescue settings, and design products that respond as needed in every situation.

With our complete range of hydraulic cab tilt components, Power-Packer can work with you to develop a cab tilting system perfectly matched to meet the weight and specs of your cab.

- Many customization options are available – choose from electric, air, or manually powered pump and we can design the system for you.

- Many standard cylinder and latch options are available to create the best fit possible.

- Hydraulic latches secure heavy cabs for safe travel and can be supplied with either visual or electric engagement indicators.

- Enhance safety by allowing for quick and easy access for any repairs or service. Integrated velocity fuses in the cylinders safely control the rate of descent of the cab when the work is done.

If our standard components do not meet your needs, Power-Packer engineers can design a cab tilt system with custom components to your exact specifications.